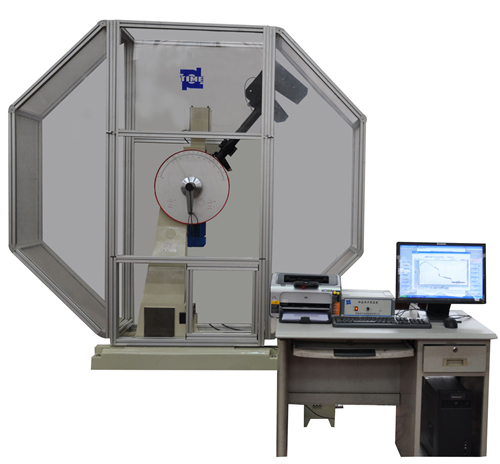

Brief Introduction: Instrumented Impact Testing Machine, also called Oscillogram Impact Testing Machine, is an ideal equipment to conduct dynamic impact analysis of metallic materials. The fracture behavior of metallic materials is normally evaluated under static and quasi-static loading conditions. However, in real life, the components may experience dynamic loading during events such as accidental overload. It is therefore imperative to study and understand the crack resistance behavior of materials during such dynamic loading conditions.

Standards :ISO14556:2000 Steel-Charpy V-notch pendulum impact test-Instrumented test method

ASTM E23 - 07ae1 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials

GB/T19748-2005;GB/T3808-2002;GB/T229-2007;GB/T18658

Features:

◆ High stiffness load frame & base to guarantee the stability.

◆ Refined swing rod with high stiffness prevented the shaking of pendulum after the test

◆ High precise photoelectric encoder to measure the angle. The whole system adopts a lot of mature Optoelectronic Technology and Optoelectronic seclusion technology to improve the measuring precision and stability.

◆ The machine can not only be operated by software, but also by control box. Dual control way improved the flexibility of machine operation to improve the working efficiency.

◆ The software can not only examine the energy, return zero, loss of energy, swing circle, but also can display, store, print the testing result through computer

|

Specification |

JB-W750 |

|

Max. impact energy |

500J/750J |

|

Pendulum moment |

267.9492NM/ 401.9238NM |

|

Max. impact speed |

5.4~5.58 m/S |

|

Rising Angle |

150º |

|

The distance between centres of Pendulum and specimen |

800 mm |

|

Span specimen plate |

40 mm |

|

The radius of specimen plate round circle |

R1-1.5mm |

|

The radius of striking edge round circle |

R2-2.5mm |

|

Corner dimension of striking edge |

30 degree |

|

The thickness of impact blade |

16 mm |

|

Min. resolution of computer display |

0.1J |

|

Outer dimension |

2300x600x1400 mm |

|

Weight |

1500 KG |

|

Power supply |

AC 380V, 50Hz, 3 phases 4 lines, 550W (main motor) |

|

Size of specimen |

10 x 10 x 55 mm |

|

|

10 x 7.5 x 55 mm |

|

|

10 x 5 x 55 mm |